See a more generalised

Submarine Matters discussion on why a country may or may not want AIP at

Air Independent Propulsion (AIP) Issues of April 23, 2015.

If Australia selected an air independent propulsion (AIP) technology for conventional diesel-electric submarines it would be on a new-construction Future Submarine rather than being retrofitted to the current Collins subs.

Much of the following information draws on Australian Dr

Carlo Kopp’s article originally published in Defence Today, December 2010. Much information is also drawn from Edward C. Whitman’s article with some major updating.

Some AIP Attributes When Selecting

In assessing the merits of any AIP system several factors,

which include potential weaknesses, are important, including:

• Submerged endurance achievable with an Australian specified

profile, comprising specific segments of submerged operation at specific speeds

and depths, representative of real missions;

• Suitability of the AIP to Pacific, Indian and Southern

Ocean operating environment as distinct from the North Atlantic-Baltic

operating environments of most AIP builders;

• Acoustic signature contribution produced by the AIP

system in specific operating regimes, but especially at varying speeds and

depths;

• Vulnerability of the AIP systems (especially hydrogen or

oxygen storage) to near miss explosive or implosive effects that otherwise not

lethal to the submarine or its systems;

• Various failure modes of the AIP system and its

oxidiser/fuel storage, and to what extent are these repairable if a failure or

battle damage arise in a contested patrol area;

• Failover modes and internal redundancy in the AIP

system, and what ‘casualty’ modes exist if a catastrophic failure arises to get

the boat out of danger;

• Replenishment options (if any) of oxidiser and fuel

from a tender when operating at large distances from a friendly port;

• Up-front costs of AIP systems in dollar amounts and as

a portion of the total cost of the sub;

• Lifecycle cost of operating and maintaining the AIP

system, at a representative operational-tempo.

In the final analysis, any AIP system will need to be

subjected to some representative and tough testing before it even makes a

shortlist (which may rule out the Russian and Spanish technologies which are

only at a developmental stage). This is because AIP is becoming a mission

critical single point of failure for the submarine in a combat environment. If

the AIP system fails for whatever reason while the submarine is operating in a

contested area, it may not have the option of snorkelling home.

The strength of AIP includes it being very quiet. More

than two weeks submerged with a submarine immobile or moving slowly. AIP extends

operating range but cannot drive the submarine at anything over low speed for

medium to long ranges. Can AIP be seen as a form of backup if specific portions

of the diesel-electric drive-train fail?

AIP Technologies

These are arranged by what I consider the likelihood that

Australia might select a foreign company and/or submarine which utilises that

technology.

Fuel cell systems – German PEM

Fuel cell - PEM AIP is likely if Germany’s TKMS is

selected to build Australia’s Future Submarine.

Operation - Fuel cell based AIP systems typically employ

a hydrogen oxygen fuel cell to generate electrical current, which then powers

the boat’s systems. The principal issue in operating any fuel cell based system

is the manner in which the oxygen and hydrogen are stored (physically and

chemically) prior to introduction into the fuel cell. The available technology

is the Polymer Electrolyte Membrane (PEM)

cell used in the Siemens SINAVY AIP fuel cell modules.

The oxygen supply is stored as LOX in the PEM system. The

hydrogen propellant supply in the PEM system is described as via “reformer gas”

in some documents, or solid metal hydride in others. The former scheme

typically involves the decomposition of a hydrocarbon fuel to generate

hydrogen. The fuel cell can operate by

recharging the subs batteries or in the case of the PEM directly feed the

electric motor. The fuel cell produces distilled water as a waste product.

Strengths - A virtual absence of moving parts, except small pumps, which makes this AIP exceptionally

quiet in terms of machinery noise and cheaper and easier to maintain compared

to other AIP technologies. The PEM fuel cell only operates at 80 ° C reducing

heat signature and cooling problems. PEM is relatively efficient 70% of energy (on what measure? Of LOX?),

because the fuel cell directly feeding the electric motor. PEM has been

successfully incorporated into many German Navy and export submarines.

Weaknesses - Fuel cells have a relatively high up front

cost. Fuel cells are relatively difficult and expensive to retrofit or cannot be retrofitted? Does PEM AIP

generally produce less average power than Stirling or MESMA? Is there less “dash

speed” in an emergency? The process of storing and replacing on board

hydrogen and LOX involves significant safety hazards.

More Details - Fuel cells are employed in the German HDW

built Type 212 (with nine 30-50 kW fuel cell units) and two 120 kW units are

fitted on Dolphin class, on internationally marketed Type 214 subs and on some

Type 209 mod subs.

It is unknown whether the two Type 218SG subs being built in Germany will utilise fuel cell PEM or Stirling engine AIP. If it is Stirling (an AIP Singapore is already familiar with in the two Archer class) then that might be one reason that the new submarines have been called "218" rather than "214"

.

Methanol defragmentor is the latest AIP being considered - German, France and Spain may be ahead in this.

Indian DRDO Fuel Cell - A March 2014 report indicated Naval Group (was DCNS) might install a DRDO developed AIP based on hydrogen fuel cell technology on one [or more] of the six Scorpenes beinge built at Mazagaon Dock under Indian Navy Project 75. This was in preference to an older version of French MESMA being offered for the Project 75 Scorpenes. The DRDO fuel cell might be also be built into the second line of Indian future conventional submarines under a different project, known as P75I.

---

Now Saab and FMV's Stirling AIP system.

Stirling-cycle heat engine with external combustion

Stirling Engine

Stirling AIP is another strong contender for Australia’s

Future Submarine if Japan’s Soryu drive-train or a direct purchase from Sweden (Saab)

is selected.

In the Stirling cycle, heat from an outside source is

transferred to an enclosed quantity of working fluid - generally an inert gas -

and drives it through a repeating sequence of thermodynamic changes. By

expanding the gas against a piston and then drawing it into a separate cooling

chamber for subsequent compression, the heat from external combustion can be

converted to mechanical work and then, in turn, to electricity. Like MESMA,

this approach has an advantage over internal combustion systems, such as the closed

cycle diesel (below) in that the combustion processes can be kept separate from

those that actually convert heat to mechanical work. This provides significant

flexibility in dealing with exhaust products and controlling noise.

The Swedish developed Stirling system employs LOX as the

oxidiser and diesel as the fuel, which are combusted at a pressure higher than

that of the surrounding water mass permitting the exhaust to be directly vented

to sea. The Stirling engine is coupled to a generator that feeds into the

boats’ primary electrical system.

Strengths - Stirling engine are relatively

simple and less hazardess in that they just use diesel and oxygen with Stirling

engines running on liquid oxygen and diesel oil to turn a generator to produce

electricity to charge the sub's batteries. Stirling technology has been widely

used by several navies including Sweden’s (current Södermanland and Gotland

class), Singapore’s (two Archer class), Japan’s (Soryu class) and some Chinese

PLAN SSKs.

Weaknesses – Its moving parts can contribute to

noise. The Stirling engines operate at a pressure of 20 bars, which limits the

submarine’s depth capability to 200 meters, unless an exhaust gas pressure

intensifier mechanism is used. As with other AIP systems that burn LOX

and diesel, the LOX supply is the principal constraint to achievable endurance.

More Details - On Sweden’s Gotland class

subs there are two 75 kW Stirling engines for propulsion or charging batteries.

The endurance of the 1,500-tonne boats is around 14 days at 5 knots (5.8 mph;

9.3 km/h). Japan’s Soryus (of the size and tonnage expected for

Australia’s Future Submarine) utilise four 75 kW Kawasaki Kockums V4-275R

Stirling engines

---

MESMA closed-cycle steam turbine

Closed cycle steam turbine - French "MESMA"

French "MESMA" closed cycle steam turbine systems could be compared to

nuclear systems, in that heat is used to generate steam, which via a turbine or

turbo generator charges the batteries that power the electric motor. Stored

oxygen allows the fuel to burn creating the heat.

Naval Group (was DCNS) in France offer the MESMA (Module d’Energie

Sous-Marine Autonome) system in lengthened Agosta or Scorpene class subs. Fitting MESMA requirers the insertion of a hull section about 8.3 metre long, weighing around

305 tonnes. The MESMA system burns ethanol, using stored liquid oxygen LOX as the oxidiser.

The propellant mix is burned at 60 atmospheres at up to 700° C, which implies a need

for seawater cooling. Naval Group claims MESMA triples the submerged endurance of non-MESMA subs.

Strengths – Relatively high output power is available. MESMA AIP permits faster reaction times for more rapid acceleration than Stirling of Fuel Cell AIP. Can more rapidly The

design permits relatively easy? retrofitting

into existing submarines by adding an extra hull section-plug.

Weaknesses - MESMA generates more detectable heat (and probably more carbon dioxide and monoxide) than Fuel cells and Stirling AIP. The hazards (like Fuel cells and

Stirling) of storing and handling the liquid oxygen (LOX) and ethanol. While the MESMA may

provide higher power output, its net efficiency might be the lowest (estimated

at 25%) as its rate of oxygen consumption is higher. MESMA has significant

moving parts, which may radiate detectable noise. Ultimately, the maintenance

and crew training requirements of the MESMA steam turbine system are significant

- adding to cost. The burning process yields exhaust carbon dioxide

which needs to be expelled behind the sub at any depth perhaps making it

vulnerable to advanced airborne and ASW ship sniffing sensors?

---

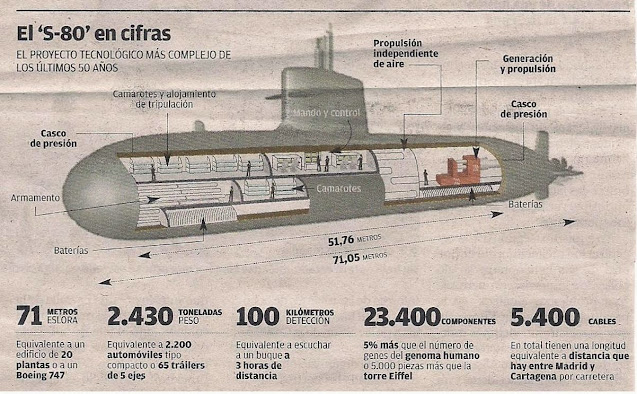

The Spanish S-80's AIP - known (in Spanish) as Propulsion Independiente de aire.

Spanish Bio-ethanol (or maybe Methanol) (Closed cycle steam

turbine?)

Though Spain’s Bio-ethanol AIP technology is not fully

tested and of course hasn’t been used in practice Australia has a counter-intuitive purchasing history of untried military technology. This would be in

the context of Australia selecting the not fully tested or even deployed

Navantia S-80 Isaac Peral class submarine.

The S-80 AIP technology under development is purportedly

“completely different” from MESMA. The S-80's AIP system is based on a

bioethanol-processor consisting of a reaction chamber and several intermediate

Coprox reactors, that will transform the BioEtOH into high purity hydrogen. The

output feeds a series of fuel cells.

The Reformator is fed with bioethanol as fuel, and oxygen (stored as LOX) generating hydrogen

and carbon dioxide as subproducts. The produced hydrogen and more oxygen is fed to the fuel cells.

The bioethanol-processor also produces a stream of highly

concentrated carbon dioxide and other trace gases that are not burned

completely during combustion. This gas flow is mixed with sea water in one or

more ejector venturi scrubber and then through a CO2 Removal System and whose purpose is to

dissolve the "bubbles" of CO2 in

water to undetectable levels.

The oxygen and fuel flow rates are directly determined by

the demand for power. The AIP power in the S-80 submarine is at least

300 kW. A permanent-magnet electric motor moves a fixed propeller of a

special design, that doesn't create cavitations at high speed.

Weakness – Sounds highly complex. Cost unknown and cannot

currently be estimated. Undeveloped. Unused even by the Spanish Navy. This problematic

formula of claims may increase the chances of Australia selecting it.

---

Closed cycle diesel (CCD) systems

Australia almost definitely won’t buy this AIP system.

http://www.navy.mil/navydata/cno/n87/usw/issue_13/propulsion.htm

indicates “CCD systems have been developed by a number of firms in Germany,

Britain, the Netherlands, and a few other countries. However, except for a

300-horsepower demonstration system refitted onto the German Navy's ex-U 1 in [1992-]

1993, no modern CCD systems have entered naval service. England's Marconi

Marine recently acquired CCD pioneer Carlton Deep Sea Systems and is marketing

a CCD retrofit package for existing conventional submarines, such as South

Korea's nine Type 209s. Although one key advantage of CCD systems is their

relatively easy backfit into existing submarine engineering plants, there have

been no takers. Despite the additional supply complication of needing regular

replenishment of cryogenic oxygen and inert gas, there are logistics advantages

in retaining standard diesel engines and using normal diesel fuel.”

---

Russian Kristall-27E AIP as it may appear on a yet to be developed Russian Amur-Lada-Kalina conventional submarine. (Sourced from here)

Russian Kristall-27E AIP

Russia hopes that it could develop the 4th generation Lada-Amur class have been discontinued because Russia has been unable to develop satisfactory air independent propulsion (AIP). This makes prospects for an Amur class from dim to nil.

January 2016 reports from Russia are that Russian AIP (essential to market Lada or Amurs) has not been developed hence additional Ladas (after L2 and L3) and any export Amurs will no longer be built. Prospective Amur customers have probably been offered the existing Improved Kilo (636) class instead. This is assuming customers (other than China) would not accept a Russian offer of a future "fifth generation" Kalina class SSK - with the Kalinas only likely to be operational (with AIP) in the Russian and maybe Chinese Navy in the mid 2020s.

Russia is far behind Western countries in fully developing and actually

deploying AIP systems. Russia has been talking about its untested Kristall-27E

AIP for at least 12 years.

Kristall is described as a system with alkali matrix

electrolyte, intermetallid storage of hydrogen, cryogenic storage of oxygen and

a low-temperature electrochemical generator. See Kristall-27E AIP

described in great detail here and here.

Strengths – None verifiable as yet.

Weaknesses – Its Russian - unpopular with the Australian

military. All of this Russian originated description appears to be marketing

claims in place of full development and deployment. It appears that Russia is

not developing AIP for its own submarine corps but instead may develop it if foreign customers places orders for AIP submarines. The risk appears to lie

with customers during a lengthy development phase. This may explain why

customers have restricted their purchases to non-AIP Kilos - that are less

expensive and less technically risky than AIP Amurs-Ladas. It will be interesting if

the Kalinas sell - though we are talking years of development.

---

Nuclear Propulsion

While politically unpopular with Australia’s previous

(Labor) Government nuclear power is the ultimate AIP as it presents no

restrictions on submerged time, range or operation at a sub’s maximum speed.

Arguments like “we couldn’t train Australian nuclear

technicians-engineers (or hire US-UK personnel) within 20 years to operate or

maintain submarine reactors” appear to be poorly argued, but current, conventional

wisdom.

For the usual safety reasons such Australian SSNs could be based at Fleet Base West, Rockingham, Western Australia which US SSGNs and SSNs already regularly visit.

Conclusion

Using any of the AIP technologies would involve lengthy selection processes. Extensive foreign and local training would be required for the technicians, engineers, officers, crew and officials required to maintain, use, administer and repair these technologies. All this takes years and in many cases decades. AIP technologies need to interact with the complete submarine weapons system - so can't only be seen or assessed in isolation.

Sources Used Include

Pete

.jpg)