Pete thanks wispywood2344 for his May 15, 2021, 1:34:00 PM advice that the Japanese Soryu Mk.II and Taigei-class submarine Lithium-ion Battery (LIB) formula (confidentially termed "SLH") is, in fact, LCO, ie. Lithium Cobalt Oxide (LiCoO2)

Wispy notes LCO is a different substance

from the other LIB formula "NCA" ie. Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) believed to be intended for Japanese submarines.

Wispy's comment that Japanese submarine's current LIB formula being LCO takes into account:

- the

development period and technology trend of LIBs and

- Japanese language GS Yuasa Technology Co Ltd. (GYT) document which Wispy deems "highly reliable" with link https://ssl.bsk-z.or.jp/kenkyucenter/pdf/gyt20201210.pdf .

That document was written by employees of large battery producing company GS Yuasa and Mitsubishi Heavy Industry (MHI):

Pete has now translated this document:

TITLE: “Realization

of the world's first submarine equipped with a lithium-ion battery system”

DATED: [noting the most

commonly used date format in Japan is "year month day”] “20201210” means December 10, 2020.

BY: Takahiro Ida,

Hidefumi Hasegawa and Kazuyuki Kawamoto all of GS Yuasa Technology Co., Ltd. and by Hiroshi Tonomoto and Ken Nitta of the Defense and Space

Segment, Submarine Engineering Department, Ships and Special Machinery Division

of Mitsubishi Heavy Industries Ltd.

"1. 1. Introduction

GS Yuasa Technology Co., Ltd. (GYT) has been manufacturing

lead-acid batteries for submarines for many years.

Based on this abundant battery building experience we

will mass produce lithium-ion batteries for submarines.

We have completed the development of

lithium-ion batteries [LIBs] for submarines that match the quality and performance

required for submarine use.

Mitsubishi Heavy Industries, Ltd. (MHI)

has made lithium-ion batteries safe and fully functional.

We have developed a [computerized onboard submaine] main storage battery management [and safety] control device

for LIBs on submarine. GS Yuasa and MHI signed a mass production contract for LIBs on submarine with the Japan's MoD Acquisition, Technology and Logistics Agency (ATLA) in 2015.

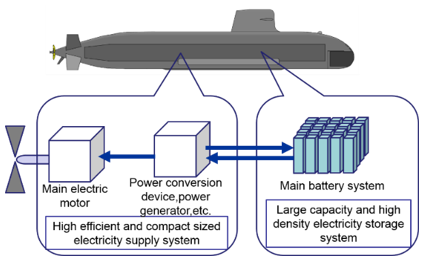

[ Pete Comment: See "Research on high-efficient electricity storage and supply

system for submarines" on ATLA website here at https://www.mod.go.jp/atla/en/soubi_kansen.html with the ATLA diagram and description below:

[ATLA explains] "Conduct research on electricity storage system with large capacity and high density, electricity supply system with high efficient and compact sized to extend submarines’ underwater endurance without increasing ship size." ]

GS Yuasa Technology Co., Ltd. (GYT) started mass production of LIB batteries in March 2017. This proceeded smoothly. In August 2018 GS Yuasa Technology Co., Ltd. (GYT) delivered them to MHI.

After that, the submarine [Soryu Mk. II] JS Oryu was equipped with lithium-ion

batteries. The main storage battery computerized management device was integrated into Oryu from the

summer of 2019.

After JS Oryu's sea trials, Oryu [with its Lithium-ion Batteries] was handed over to the [Japanese Navy] Maritime

Self-Defense Force in the spring of 2020.

2. 2. Development history

GYT established mass production technology for lithium-ion

batteries around 1993, and lithium to be installed in submarines in 1994.

GYT proposed the development of an ion battery to MHI's Technical Research and Development Institute (TRDI) [see ATLA's precursor TRDI] at that time under MHI.

In 2003, GYT and MHI's TRDI were contracted to develop "new main storage battery for submarines. [likely by Japan's Ministry of Defense (MoD) which likely provided startup, ongoing and on completion funding].

Participated in "Research Trial"

GYT, conducted

research trials, and completed the development of lithium-ion batteries for

submarines.

3. 3. Development overview

3.1 Lithium-ion battery

Lithium-ion batteries [LIBs] generally have the following superior

performance compared to lead-acid batteries, so they are used in submarines.

LIBs should contribute to improvements of

performance, due to.

・ High energy density: Can store more power and discharge

・ Long life: Reduced number of battery replacements

・ High charging efficiency: Shortening charging time

・ Excellent discharge characteristics: Sufficient capacity

can be taken out even with a large current.

・ No hydrogen gas generation: [So no need to take safety

measures against hydrogen gas].

・ No maintenance required: No battery maintenance required

・ No maintenance required: No battery maintenance required

Figure 1 [can be seen on Page 2 of the original document] shows the external view of the new lithium-ion

battery (hereinafter referred to as SLH type) developed by GYT.

The SLH LIB's dimensions are specifically designed to be the same size as the preceding lead-acid batteries.

The lead-acid battery was a single cell, while the SLH type

configuration is an aggregate of 10 cells arranged in 2 rows

and 5 stages and connected in series. Table 1 [also on Page 2 of the original document] shows the main points of the SLH

type.

Table 1 indicates Lithium cobalt oxide, which can achieve high

energy density, is used as the positive electrode material.

In addition, as will be described later, the SLH type is

equipped with a battery monitoring unit that measures the cell voltage and cell

temperature at the top.

[From documentDetails]

Fig. 1 External view of the new main storage battery SLH

type

Table 1 Key points of the new main storage battery SLH type

[Table 1 literally translated is:]

Table 1 Key points of the new main storage battery SLH type

Item New main storage battery SLH type

Structure sealed type

Electrolyte Organic electrolyte

Positive electrode material Lithium cobalt oxide [LCO]

Negative electrode material carbon.

3.2 Battery monitoring unit

Unlike the conventional SCG type lead battery, the SLH type

is equipped with a battery monitoring unit. Figure 2 [which can be seen on Page 3 of the original document] shows the battery

monitoring unit.

The external view of the device is shown. This battery

monitoring unit monitors the voltage and temperature of each cell that constitutes

the main storage battery.

It is an electronic device that measures the degree and

transmits the results to the main storage battery management device [central computer station terminal]. [This station provides details of any] performance degradation or safety degradation.

Therefore, the station is used to confirm that the battery is working in the correct voltage range and operating temperature range.

In order to ensure [accuracy and safety] the [station video screen] is composed of two

completely independent units for regular use and supplementary use, and [can operate] automatically in the event of an [emergency] failure on the regular side.

It switches to the auxiliary side. See Fig. 2 External view of the battery monitoring unit [which can be seen on Page 3 of the original document].

3.3 Battery management system

Monitors and displays the temperature and voltage of many

cells mounted on the submarine in real time, and data in each control device, etc.

It has a function to send (battery status). The main storage

battery management device is serially communicated from the battery monitoring

unit.

Receive data at SCC (Ship Condition Control Console) or

automatic charging device

Send the required data. In addition, it consists of two

sides, one for the front group and one for the rear group, and all the front

and rear groups are single on each monitoring screen.

It is possible to display the battery status.

Fig. 3 Battery monitoring system (joint image) [which can also be seen on Page 3 of the original document]

4. Summary

By installing the new main storage battery SLH type on a

submarine, the following two points are the effects that contribute to the

performance of the submarine.

Can be mentioned.

(1) Compared to lead-acid batteries, SLH LIBs have a higher energy density,

so they are smaller and lighter.

[More SLH LCO LIBs, with higher energy density, can fit into the limited space of the submarine. This is compared to larger, lower density "SCG" lead-acid batteries.] [Direct translation:] Equipped with SLH type, which has higher energy density than

SCG type lead battery, in the limited volume inside the submarine.

By doing so, [SLH LCO LIBs] can contribute to the extension of the

underwater duration.

(2) No hydrogen gas is generated. Moreover, there is no need

to manage the specific gravity measurement.

[SLH LCO LIBs make] maintenance management becomes easier [compared to] the measurement and

adjustment of electrolyte specific gravity and liquid level, etc., [necessary with the older] SCG type [lead-acid] batteries, etc.

No maintenance work is required.

5. Acknowledgments

We are very honored to receive the Honor of the Defense

Infrastructure Development Association Award.

We will continue to do our best to meet your expectations.

In this development, a large number of people concerned,

including the Ministry of Defense [MoD] and the Acquisition, Technology and Logistics

Agency [ATLA] will be enormous. [ie. they have made an enormous effort.]

We are deeply grateful for [the Japanese Government's, mainly the your guidance and encouragement.

That is all."

[Documents ends]

-----------------------------------

See also this other GS Yuasa document, pages 14, 28 and 31, on GS Yuasa supplying LIBs for Japanese submarines.